What is carbon arc welding? This is a question that many people have, but don’t know where to find the answer. In this blog post, we will talk about what carbon arc welding is and how it works. We will also discuss some of the benefits of carbon arc welding. If you are considering learning this type of welding, then this blog post is for you.

What is Carbon Arc Welding?

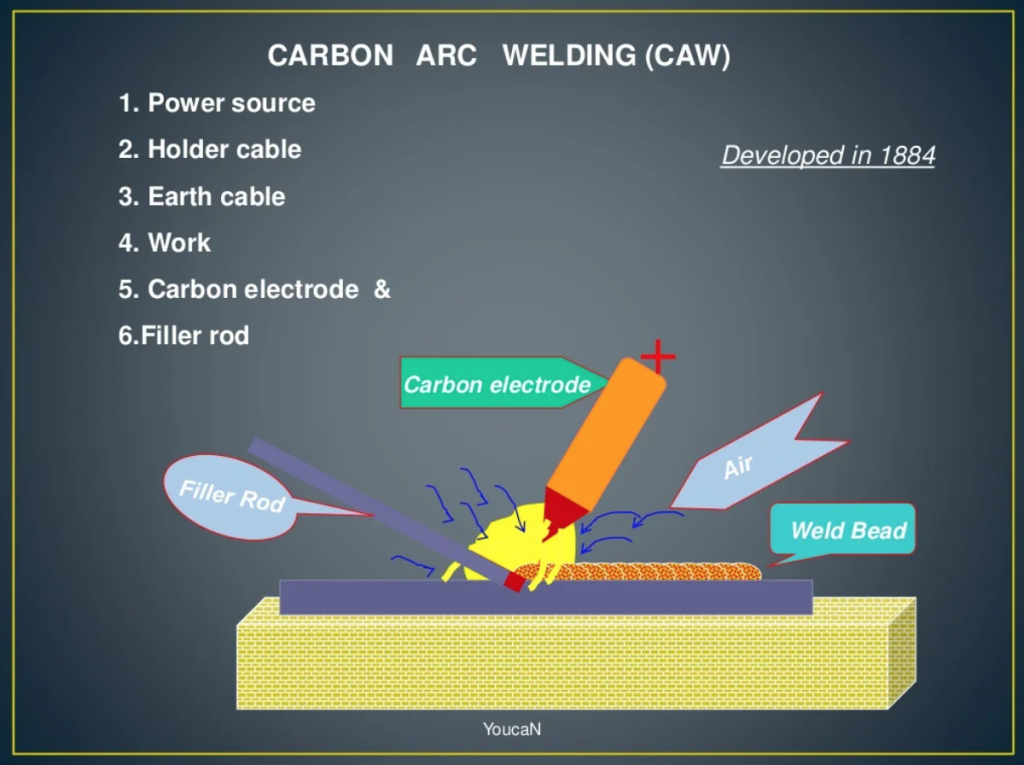

Carbon Arc Welding (CAW) is an obsolete welding technique in which a low-voltage, high-amp current arc is produced between the carbon electrode and workpiece or between the two carbon electrodes.

The process of carbon arc welding is a welding technique in which metals are welded by an electric arc between the workpiece and a non-consumable carbon electrode. Previously, carbon arc welding has been quite a popular welding method, but it has been largely discontinued today.

Carbon arc welding uses a DC supply

Only DC power may be used for carbon arc welding. The heat from the arc melts a pool of molten metal, and the extra metal required to weld is delivered by a filler rod made of the same material as that of the melting substance.

Advantages of carbon arc welding

- Lower-cost equipment is used in this procedure. As a result, you won’t need to spend a fortune on this method, as the equipment needed for this welding is quite inexpensive.

- It’s simple to set up and use. Carbon arc welding is easy to do. You may simply automate this whole welding procedure.

Disadvantages of carbon arc welding

- The quality of the weld produced by this process can vary. The carbon electrode allows the weld metal to become contaminated with carbides. Carbon arc welding can only be performed on a DC power supply. The carbon electrode requires twice the current to reach welding temperature as a metal electrode, due in part to its increased resistance.

- If a filler is needed, the carbon arc welding process must be completed with a separate filler rod.

- Blow holes are common in carbon arc welding, particularly when welding on the edge of a workpiece.

- The arc in carbon arc welding is only used as a source of heat, and it does not contribute any metal to the weld junction.

How does carbon arc welding work?

The metal is melted by an electric arc between the electrode and the parent metal. The base metal is melted as a result of the electric arc’s heat. After the molten metal has solidified, the desired weld is produced in that area. The size of the electrode used during the process can be adjusted according to the generated current.

Single carbon arc welding process

Single-carbon arc welding is a form of carbon arc welding that involves the use of a carbon electrode, usually a galvanized sheet metal, and you are still using DC as the power source. One of the most important things you’ll learn about welding galvanized sheet metal is that it has excellent corrosion resistance. Galvanized steel, on the other hand, contains a thin coating of zinc which protects against moisture and corrosion caused by water exposure.

The single-carbon torch used in carbon arc welding is built to endure the hotter temperature of the electrodes. The major disadvantage of single carbon arc welding is that a little amount of carbon from the electrode may be introduced to the weld puddle, which can damage it.

Using twin carbon arc welding, his carbon contamination may be reduced. Twin carbon arc welding is one of the many types of carbon arc welding processes. TCAW is, however, a little different from carbon arc welding.

What is the twin carbon arc welding process?

The twin carbon arc welding process is a specific type of carbon arc welding that uses two carbon electrodes to generate the arc. The torch employed in twin carbon arc welding differs from the usual kind of welding torches. It has two arms that hold the two carbon electrodes at precise angles.

The welder uses carbon electrodes to weld. The distance (or gap) between the two carbon electrodes is changed by the welder during the welding process. The alternative current source (AC source) is what we use to power twin carbon arc welding.

The welder connects the carbon electrodes and then spreads them out to a distance during this process. Because of this, the arc is produced at the top of the electrodes, resulting in a high temperature that is enough to melt a filler rod.

What electrodes are used for carbon arc welding?

Carbon arc welding is a method of joining two pieces of metal using electrodes that are baked carbon or pure graphite-coated inside a copper sheath. During welding, the electrode is not consumed as the weld progresses; however, due to erosion, electrodes will have to be replaced over time.

Carbon arc welding heats up to 9000 degrees Fahrenheit, and the resulting light is so bright it’s called “white sun.” When welding, keep the light to a dull red or orange. This bright light may be harmful to welders if they do not wear the required eye protection and clothing.

Carbon welding electrodes

Carbon electrodes are typically 6 inches long and range in diameter from 3/16 to ½ inches.

The electrodes are positioned in electrode holders, which are identical to SMAW’s. The carbon electrodes are available in two forms: baked carbon electrodes and graphite electrodes. Because the arc is ‘hard’, it makes more noise and is difficult to handle. It also produces a ‘soft’ arc that makes less noise and is easier to control. The cracked electrodes produce a little bit of noise while operating, but they last much longer.

Carbon arc welding requires carbon or graphite electrodes that are 300 mm long and 2.5 – 12 mm in diameter. Graphite electrodes can withstand more current, but their arc column is more difficult to manage.

Need guidance on selecting the right electrode holder? We have an article for that

Conclusion to carbon arc welding

Welders who are new to carbon arc welding should start with twin carbon arc welding. This process is a little different from carbon arc welding, but it is easier to control and produces less noise. The twin carbon arc welding process uses two carbon electrodes to generate the arc. By using twin carbon arc welding, you can reduce the amount of carbon contamination that may be introduced into the weld puddle.

Thanks for reading! I hope this article helped you understand carbon arc welding a little better. If you have any questions, feel free to reach out to us. Until next time, happy welding.