Welding has come a long way since the first sparks were struck. This ancient process has been used to join metal objects together for centuries, and its popularity continues to grow. In this blog post, we will take a look at the history of welding and explore some of the major milestones that have been achieved in this field. Stay tuned – we have some exciting things in store.

The history of history of welding

The history of fusing metals through welding dates back to 3000 B.C., when humans first started working with bronze. The oldest known examples are small golden boxes that date from around 2,000 years ago, found in ancient Egyptian ruins!

These early welders used charcoal as a utensil or weapon. They would heat pieces until they turned into vapor and then use their hands to form them together. Sometimes even putting out the fire between metal objects using water so no flames could spread too quickly. That seems dangerous now doesn’t it! It’s really exciting how much there is still unknown about this fascinating practice despite its age.

The invention of the arc welder led to easier ways to weld metals together to create steel structures like cars and buildings. The heat created by an electric arc allowed metal pieces to be melted together quickly. Instead of using heat or fire to melt them which was much slower and dangerous work. As time went on, new technology made it possible for people all over America (and other countries) could start their own business as a welder.

Welding’s humble beginnings

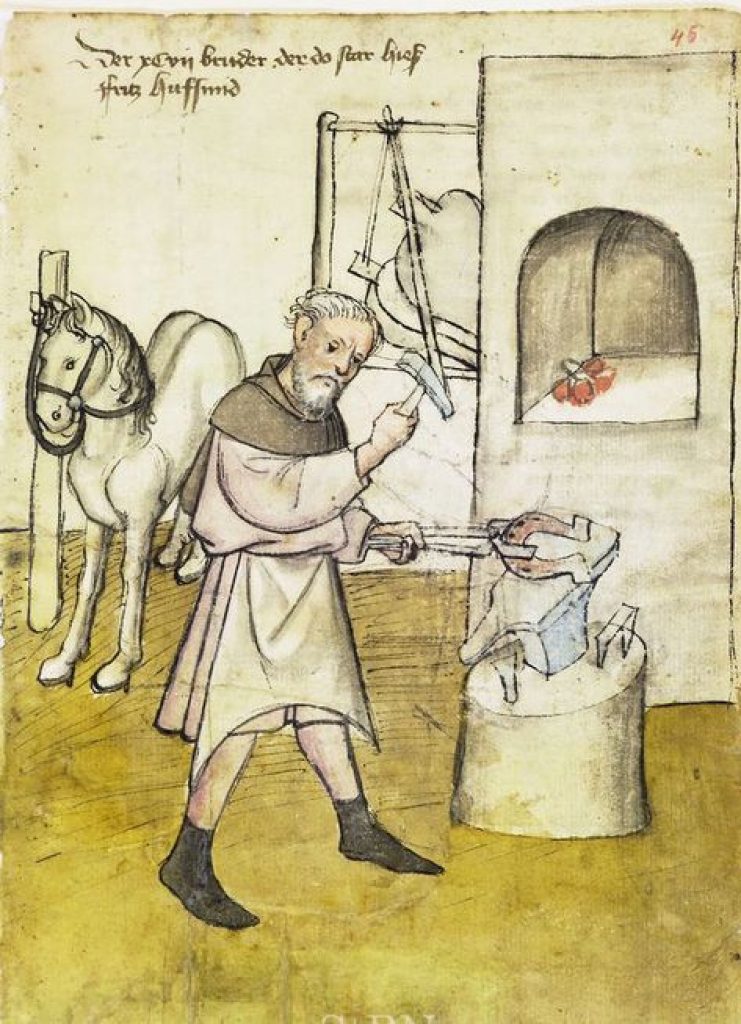

Did you know that welding was used as early as the 1400s? Welding is a process where two objects are heated and melted together so they form one solid object. The first welders were blacksmiths, who traditionally use fire to heat metal for shaping it into tools and other objects. In the 1800s, inventors started using electric currents to power their machines instead of fire.

Today, we have modern-day welding equipment that allows us to quickly fuse metals without having to manually hold them in place with clamps or turn a crank handle. Just push a button.

First welding machine

The Industrial Revolution created a demand for welding that had not been seen before. As early as 1800, Humphry Davy found an electrical arc between two carbon electrodes using battery production methods to be capable of softer metal joining together in one piece with less thermal damage than other processes at the time.

The rise and success is accredited mostly due its increased versatility. This made it more practical on large projects like shipbuilding where welders needed greater mobility. They could travel about freely within confined spaces rather than rely heavily upon scaffolding like supports used by later generations looking back on their own history.

Welding in Mid 20th century

Welding has been a popular method for bonding different types of materials since the early 20th century. Gas tungsten arc welding, created in 1941 and now more common than ever before thanks to its safety properties that allow welders to fuse together many nonferrous metals with great success rates at high temperatures without risk for melting or contaminating nearby components on an industrial scale.

Over the centuries, welding has evolved into an incredibly complicated process. Used for construction in both space exploration environments as well as on Earth. There are more than 90 different types of welding processes out there with many modifications and revisions.

Modern-day welding

Today, there are several different types of welders including manual grinders and oxyacetylene torches. Plasma cutters can be used for complex jobs but they’re not as common in the industry because it takes more training to use them properly. TIG welding is mostly reserved for large projects or when another type isn’t available at all due to equipment limitations.

A good understanding over what kind you’ll need will depend heavily on your project’s requirements; whether its metal construction with some plastic components – these would require an MIG welder– if nothing else though every production facility should have access both gas shielded versions that operate using helium instead operating under pure atmospheric pressure .