If you are looking for an industrial-grade spot welder, the Pro spot welder i5 is a great option. This machine is perfect for welding heavy-duty materials like steel and aluminum. It has several features that make it easy to use, including an LCD that shows the voltage and amperage settings. In this review, we will take a closer look at the Pro spot welder i5 and see why it is such a popular choice among welders.

Pro Spot i5

Welding output: 14,500A max

Liquid cooling system: Radiator / pump active loop

cooled to the weld caps

Weight: 314 lbs

Overview

According to the amperage, time, and pressure settings, the i5 is capable of producing extremely precise welds.

The new medium frequency trans-gun in the i5 can deliver over 13,000A with over 1,000 lbs of squeeze force, designed to work with all new ultra high strength steel.

Features

The Pro Spot welder i5 has three operating modes: AUTO, SEMI-AUTO, and MANUAL. The i5 measures the thickness of the metals through complex optical equipment.

The i5 detects the metals to be welded from a pre-delivered current, determining the sort of metal. With the press of a single button, the i5 produces optimum weld power based on the thickness and resistance feedback it receives, regardless of material or thickness.

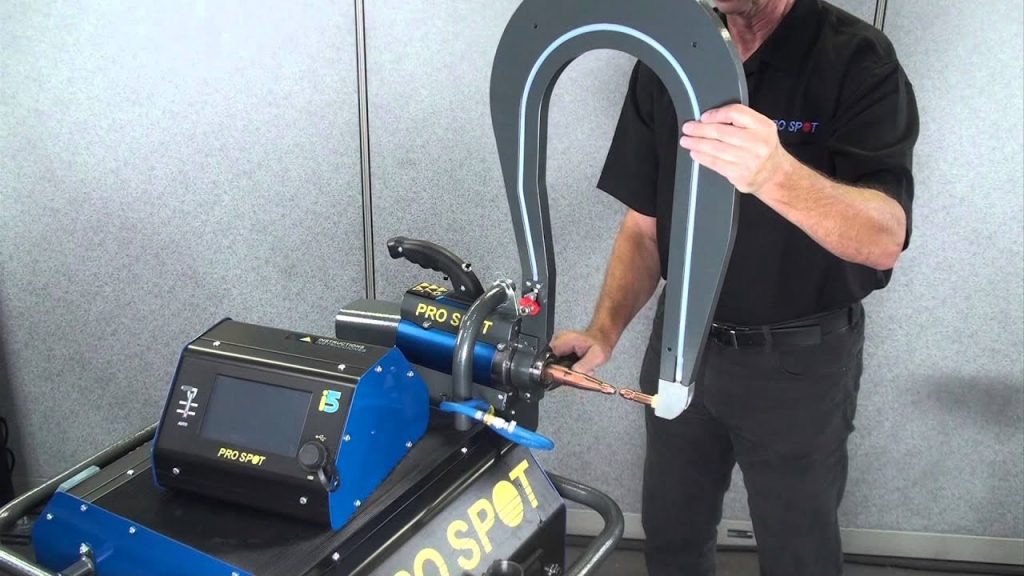

Double-Acting Trans Gun

The double-acting characteristic of the spot gun is its most significant feature. The i5 can spread the electrodes wide open with a press of a button, unlike any other trans-gun on the market, and never leaves your hands from their positions. The i5’s unique feature is that it can spread the electrodes widely open with a simple push of a button without requiring the user to take their hands off their original positions.

Because Pro Spot Welder i5 is automated, the process of straightening arms efficiently removes much waste and effort. With no need to manually move or loosen their arms, workers can effortlessly return and hold their hands back in a pump handle position.

This eliminates the need to alter your holding position to release and move the weld arm manually just to then re-tighten, saving time as well as ensuring that the operator doesn’t have to change their holding posture.

Auto welding

The Pro Spot welder i5 is a cordless welder that uses arc welding. It detects the thickness and resistance of the two metals, which it uses to determine whether or not a weld should be performed with a specific amount of power. The i5 automatically calculates the correct weld power for each type of metal, thickness, and corrosion protection between them.

The operator can choose between two different modes AUTO and MANUAL for the two sided spot welding. In the AUTO mode the i5 measures the thickness of the metals automatically using the latest optical technology.

The i5 first determines the type of metal to be welded by measuring the metals to be welded with a pre-delivered current. The correct weld power is determined every time, regardless of type of metal or thickness, based on the thickness and resistance feedback provided by the i5.

Welding capabilities

The M6 features a new medium-frequency trans-gun that can deliver 14,500A with 1,243 lbs (565 daN) of electrode force.

The i5 is capable of welding different types of metals and thicknesses, as well as non-ferrous materials with a variety of resistances and weld depths. The machine’s digital intelligence accurately distributes the required weld power depending on the type of metal or thickness being welded.

Disadvantages of Pro Spot Welder i5

The only disadvantage is that you need a 3ph outlet to power it, but if you have access to one in your store, there is no better. For everyone else, the battery-operated model is the way to go, but these devices are for diehard enthusiasts.

If you’re looking for good industrial welder alternatives, don’t forget to check out our review of MIG welders.

What are customers saying

“We’ve used it numerous times. They’re really nice. Dent removal, as well as hammering down high spots, was possible with the machine. To change the tips, simply adjust them to suit the inserts and collars. The spot welding’s main limitation was keeping the tips servicable. It had interchangeable arms. It included a function that allowed you to change the tip quickly.”

— customer quote