Welding is a commonly used technique for bike frame construction. There are different types of welding that can be used, so which one is right for your bike frame? In this blog post, we will discuss the different welding types and their benefits and drawbacks. We will also take a look at some real-world examples of welding techniques used in bike frame construction. Let’s get started.

What is brazing bike frames

One of the most common ways to join two pieces is by using a filler metal that’s heated just below its melting point. As it cools, this hardens into place and creates a joint connecting both tubes without getting too hot so they can’t change shape or otherwise harm themselves while being fixed together like glue would do if used in isolation instead. With brazing all you need are low-melting temperature fillers which means they do not that well.

Welding uses a filler metal with a melting temperature lower than the frame material, so the filler melts to connect the tubes but doesn’t heat up enough to change the materials themselves. welding is often used as it leaves very few visible marks on finished frames and can be used with different types of metals. Welding produces strong joints – brazing does not usually produce strong joints because it heats up both parts and changes their properties (though some use braze welding as an alternative).

How to choose the right type of welding process

Brazing

Brazing is generally easier than welding and can be done at home with a torch. It’s also less expensive to purchase equipment, but more difficult for beginners since you need to know the proper technique before trying it out on your own bike frame. Brazing requires a lower temperature than welding so there are some drawbacks associated with using this method.

TIG welding

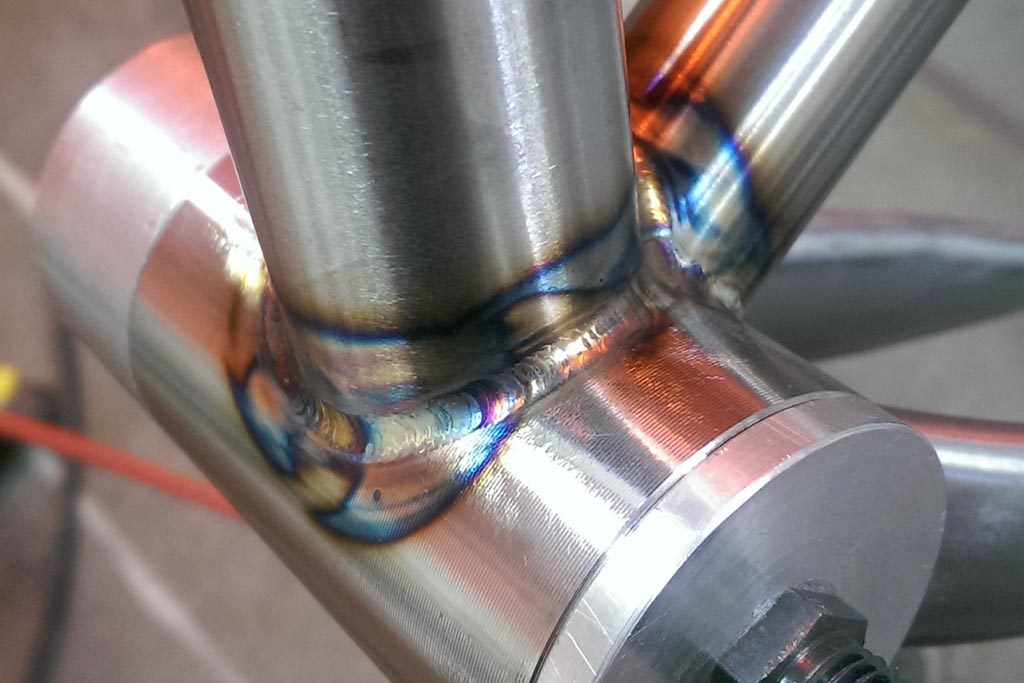

There is no welding on the frame of a bike that uses TIG welding, but it can be used for other parts such as the handlebars and seatpost. The benefits include being able to weld thinner material without overheating or melting anything nearby due to high temperatures involved in this process – making them perfect when you’re working with materials like carbon fiber.

MIG welding

MIG welding is a popular choice for bike frames because it’s relatively easy to learn and produces strong welds. It can be used on a variety of materials, making it a versatile welding option. However, there is some post-weld cleanup required with this technique, so it may not be the best choice if you’re looking for a quick and easy welding solution.

Oxy-acetylene welding

Finally, we have oxy-acetylene welding. This welding method is often used for bike frames because it’s great for welding thicker materials. However, it can be more difficult to use than some of the other welding techniques since you need to know how to adjust the flame properly. It’s also important to note that oxy-acetylene welding can be dangerous if not used correctly, so it’s best to learn from a professional before trying it out on your own bike frame.

Lugged brazing bike frames

Lug welds are usually made from steel tubing with a thin layer of brass applied over it. The welding process is done by heating up the brass and melting it into the seam between two pieces of tubing, creating an airtight seal that can withstand high temperatures without leaking or breaking apart. This type of welding requires special equipment and skill to perform correctly since there are many variables that need to be controlled during welding including temperature control, welding angle, and timing of welds.

Conclusion to welding bike frames

It’s important to consider which welding technique you’re using for your frame depending on the type of welding material and thickness, as well as what exactly it will be used for (like MIG welding or oxy-acetylene welding). You should also think about whether you want visible marks left behind by welding or if you would prefer another form of attaching materials like brazing instead. If this post has given you some helpful insights into how different types of welding could work in your next project, let us know.